Description

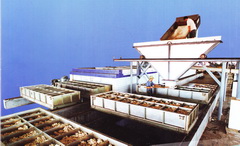

The processing line is designed to produce every kinds of TSR (technically specified rubber). We can conduct all the operations, such as breaking, washing, creping, granulating, drying, weighting, packaging, on it. The whole line can fall into two parts: the granulating line and the drying line.

The granulating line is composed of BREAKING MACHINES, RUBBER PUSHING AND CLEANING MACHINES, CREPERS, GRANULATING MACHINES OR HAMMER MILLS, DOUBLE SCREW RODS EXTRUDING AND WASHING MACHINES, CONVOYERS AND AUTO HYDRAULIC PACKAGING MACHINE.

The drying line is composed of DRYING CARS, CHAIN PUSHER, HOT-AIR FURNACES, FANS AND TUNNEL. It uses COAL or WOOD as fuel, and adopts hot-air furnaces and afterheat-circulating configuration and lowers the production –cost effectively. The furnace integrates the combustors and heat exchange device, and adopts the new technology of heat-exchanging at high-temperature stage and indirect heating. It features high-efficiency heating, rapid temperature-raising, low energy consumption, convenient installation and reliable performance.

The fans also adopt improved low-pressure, large-air-volume configuration, so makes heat circulation more smoothly in tunnel furnace. The advanced processing technology and sealing material are used for sealing and heat preservation, which makes heat circulating in tunnel furnace. It also makes the exhausting, preheating, heating and cooling areas more clearly.

We can design the line totally according to your demands.