Introduction

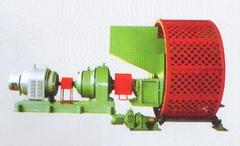

Shredding chambers are closely mated with the left-hand drive. The cutter consists of blade and hooks. The function of hooks is to catch tires special anti-wear hard alloy is built-up welded on the working face of the cutter, whichare durable and corrosion proof.

Shredding chamber is a combined structure and the cutter shafts are supported with rolling bearings, which is convenient for installation and maintenance.

The cylinder sieve or back-feed conveying unit (optional) send unqualified chips or shivers back to shredding chambers repeatedly and send out qualified ones at same time.

Transmission systems adopt Carbide-Faced Speed Reducers, which have compacted structures with higher transmission efficiency, lower nose and longer service life.

Shredder is compactly structured and practically collocated. They are easy and reliable for operation and convenient for both installation and maintenance.

Usage

Be applicable for breaking up bias or radial (steel) tires.

|

Model and Specifications |

LP-1200 |

LP-1500 |

|

Cutter Quantity |

18 |

15 |

|

Rotating Speed of Cutter Shaft |

13 |

10 |

|

Capacity (kg/h) |

2,000 |

2,00 |

|

Feeding Requirement |

Complete tires≤900 and all kinds of tread slabs |

Complete tires≤900 and all kinds of tread slabs |

|

Discharging |

Strips (60 mm wide) or blocks (60×60 mm) |

Strips (60 mm wide) or blocks (60×60 mm) |

|

Main Motor Power(kw) |

90 |

55×2 |

|

Speed Reducers |

Carbide-Faced Speed Reducers | |

|

Overall Dimension (mm) |

5,520×3,300×3,575 |

4,950×2,000×3,050 |

|

Remarks |

Before shredding tires, all bead rings should be taken off. | |