INTRODUCTION

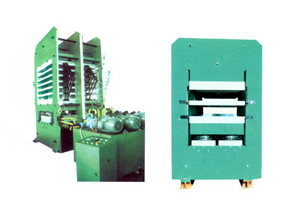

According to their structure, the machines can be divided into two catalogues: columns structure and frame structure.

With columns structure and downward pressing type, the machines` heating plates open by the weight of their selves, the platforms and plungers. The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure.

And the ones with frame structure adopt below pressing form (upwards). Under the working hydraulic pressure, the bolts ascend to make hot plate close for getting pressure, while the bolts descend by deadweight of hot plate, platform and bolt to drive working fluid to fuel reserve tank to achieve the aim of descending.

Usage

This vulcanizing machine is used for all kinds of vulcanizing rubber and plastic mold products, and non-mould products.

Specifications (column structure)

|

Type

|

XLB-DQ400X400X2

|

XLB-DQ400X400X2

|

XLB-DQ600X600X2

|

XLB-DQ750X850X2(4)

|

|

Total Pressure(mn)

|

0.25

|

0.50

|

1.00

|

1.60

|

|

Plate Size(mm)

|

400X400

|

400X400

|

600X600

|

750X850

|

|

Plate Clearance (mm)

|

125

|

125

|

125

|

125

|

|

Working Layer

|

2

|

2

|

2

|

2(4)

|

|

Piston Stroke(mm)

|

250

|

250

|

250

|

250(500)

|

|

Plate Unit Area Pressure (kg/c㎡)

|

20

|

31

|

28

|

25

|

|

Main Motor Power(Kw)

|

3

|

2.2

|

2.2

|

3

|

|

Overall Dimension (mm)

|

1300X800X1500

|

2400X550X1500

|

1401X680X1750

|

1900X950X2028

|

|

Weight(kgs)

|

1150

|

1300

|

3500

|

6500(7500)

|

Specifications (frame structure)

|

Type

|

XLB-DQ1200×1200×2

|

XLB-DQ1300×2000×1

|

XLB-Q1200×2500×1

|

XLB-Q1500×2000×1

|

XLB-Q2000×3000×1

|

XLB-Q1400×5700×1

|

|

Total Pressure(MN)

|

3.15

|

5.6

|

7.5

|

10

|

18

|

28

|

|

Platen Size(mm)

|

1200×1200

|

1300×2000

|

1200×2500

|

1500×2500

|

2000×3000

|

1400×5700

|

|

Plate Clearance (mm)

|

200

|

400

|

400

|

400

|

400

|

400

|

|

Working Layer

|

2

|

1

|

1

|

1

|

1

|

1

|

|

Piston Stroke(mm)

|

400

|

400

|

400

|

400

|

400

|

400

|

|

Plate Unit Area Pressure (kg/c㎡)

|

22

|

21.5

|

25

|

33.5

|

30

|

35

|

|

Main Motor Power(KW)

|

3

|

8

|

9.5

|

11

|

26

|

43.5

|

|

Overall Dimension (mm)

|

1685×1320×2450

|

2000×1860×2500

|

2560×1700×2780

|

2810×1550×3325

|

2900×3200×2860

|

2400×5800×3600

|

|

Weight(kgs)

|

9500

|

17000

|

20000

|

24000

|

66000

|

110000

|

XLB-D600×600 Auto Push-out Mould Hydraulic Press

INTRODUCTION

This kind of machines achieve mold put in--auto rising--auto release--reach pressure--timing--auto descend--mould put out, and enforce opening equipment is fixed.

This machine is four columns structure, including main machine, hydraulic station, PC controller three parts.

Specifications

|

|

XLB-D600X600/1.00MN

|

XLB-D600X600/1.60MN

|

|

Total Pressure (MN)

|

1.00

|

1.60

|

|

Plate Size (mm)

|

600X600

|

600X600

|

|

Plate Clearance (mm)

|

300

|

350

|

|

Working Layer

|

1

|

1

|

|

Piston Stoke (mm)

|

300

|

350

|

|

Plate Unit Area Pressure (kg/c㎡)

|

27.5

|

44.5

|

|

Overall Dimension (mm)

|

700X1650X1750

|

700X1700X1800

|

|

Weight(kgs)

|

4,800

|

5,100

|

XLB-3.00MN 650×650×1 Duplex Automatic Hydraulic Press

Specifications

|

Type

|

XLB-D650X650X1/3.00MN

|

|

Total Pressure(MN)

|

3

|

|

Platen Size (mm)

|

650X650

|

|

Plate Clearance (mm)

|

350-500

|

|

Working Layer

|

1

|

|

Piston Stroke (mm)

|

350

|

|

Plate Unit Area Pressure (kg/c㎡)

|

71

|

|

Overall Dimension (mm)

|

4450X2500X2315

|

|

Weight (kgs)

|

10000

|